Corapack

Targeting compostability as part of their sustainability commitment, Corapack selected a certified home and industrial compostable solvent-free laminating adhesive from the Sun Chemical SunLam range to produce a coffee capsule’s lidding.

An important pillar of Sun Chemical’s sustainability approach is collaborations—interacting with like-minded partner organizations and other stakeholders up, down and across the global value chains of the markets we serve.

An important pillar of Sun Chemical’s sustainability approach is collaborations—interacting with like-minded partner organizations and other stakeholders up, down and across the global value chains of the markets we serve.

Achieving industry-wide sustainability goals must be collaborative in nature, as no one entity can reach those goals on its own. Industry relationships are critical in contributing to sustainability initiatives because they help understand where there may be gaps or needs in becoming more sustainable.

Sun Chemical makes it a priority to establish relationships up and down the value chain including brands and retailers, who sell to the consumer market, which ideally creates the input for waste collections, sortation and recycling to create new raw materials.

A key element of collaborations is Sun Chemical’s participation and advocacy within respected cross-industry associations and nonprofit organizations with goals that bring the collective power of membership to deliver lasting and meaningful solutions to the most pressing environmental issues.

Here’s a list of cross-industry alliances we partner with to achieve sustainability goals for brands:

Targeting compostability as part of their sustainability commitment, Corapack selected a certified home and industrial compostable solvent-free laminating adhesive from the Sun Chemical SunLam range to produce a coffee capsule’s lidding.

In order to produce more sustainable and migration-safe paper plate alternatives, Sun Chemical partnered with Exclusive Trade S.r.l. to substitute the protective plastic layer often still found in paper-based food-contact materials by combining direct food contact SunPak DFP sheetfed inks with the SunSpec Sunstar protective varnish.

Collaboration with the VPK Group led to the conversion of their sites in France to Sun Chemical SunVisto AquaGreen technology, a range of water-based inks and coatings with high biorenewable content for reducing carbon footprint versus conventional alternatives.

The oneBARRIER PrimeCycle collaborative project with Bobst and other partners, which creates industrially viable recycle-ready mono-material ultrahigh and high-barrier flexible packaging, uses Sun Chemical polyurethane inks, overprint varnishes, barrier coatings/primers and barrier-laminating adhesives.

Coordination with the Association of Plastic Recyclers (APR) helped Sun Chemical to formulate a recycle-friendly washable ink that can be removed from post-consumer printed PET packaging in typical existing recycling processes, without staining the recovered PET flake or the process wash water. This collaboration has resulted in an acknowledgment from the APR that using the ink solution can play an important role in increasing the recycling of PET bottles.

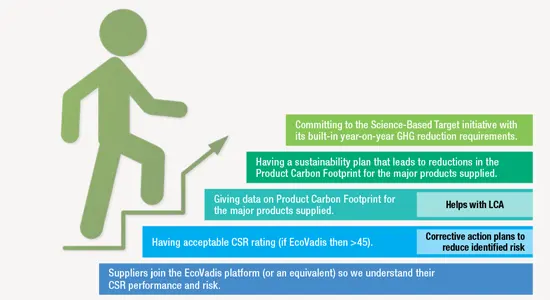

Sun Chemical continues to drive its suppliers in the direction of improved sustainability. EcoVadis is a trusted partner of Sun Chemical that provides third-party business sustainability ratings, intelligence and collaborative performance improvement tools for our global supply chain. The EcoVadis platform ranks Sun Chemical’s corporate social responsibility using a variety of categories, such as environment, labor and human rights, ethics, and sustainable procurement.

Sun Chemical continues to drive its suppliers in the direction of improved sustainability. EcoVadis is a trusted partner of Sun Chemical that provides third-party business sustainability ratings, intelligence and collaborative performance improvement tools for our global supply chain. The EcoVadis platform ranks Sun Chemical’s corporate social responsibility using a variety of categories, such as environment, labor and human rights, ethics, and sustainable procurement.

Sun Chemical utilizes EcoVadis to score its suppliers with 71% of suppliers (by addressable spend*) on the EcoVadis platform. The target for 2023 is to increase the number of suppliers on the EcoVadis platform to 80% (by addressable spend*).

Sun Chemical encourages suppliers on the EcoVadis platform to meet minimum scoring levels and requires corrective actions from those suppliers that do not achieve the targets. For suppliers that meet the scoring expectations and have no obvious risk areas, the focus changes to first getting environmental impact data for the raw materials purchased and then getting a plan that will result in those values decreasing over time.

Sun Chemical encourages suppliers on the EcoVadis platform to meet minimum scoring levels and requires corrective actions from those suppliers that do not achieve the targets. For suppliers that meet the scoring expectations and have no obvious risk areas, the focus changes to first getting environmental impact data for the raw materials purchased and then getting a plan that will result in those values decreasing over time.

For suppliers already committed to reducing their total environmental impact, we then encourage them to become part of the Science-Based Targets initiative with the expectation that 80% of our suppliers by spend, covering purchased goods and services, will have science-based targets by 2027.

(*Addressable spend is defined as situations where procurement can negotiate with suppliers to achieve business goals.)