Imagecure HT

- Exceeds industry standards for thermal cycling & thermal storage

- -40°C/+180°C for 1000 cycles

- -40°C/+170°C for 2000 cycles

- 180°C for 2000 hours storage

- Screen print, curtain coat or spray application

- Can be exposed using ‘conventional’ light source or direct image

- Low ionics

- High surface tension

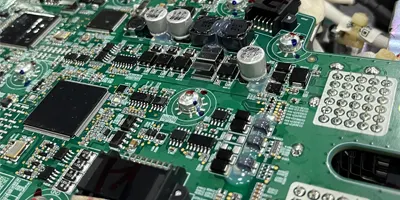

Sun Chemical offers a vast portfolio of legend inks which have excellent adhesion properties and are highly resistant to scuffing, heat and solvents when fully cured.

Sun Chemical offers a vast portfolio of legend inks which have excellent adhesion properties and are highly resistant to scuffing, heat and solvents when fully cured. Sun Chemical offers a full range of etch and plating resists for printed circuit boards that can be used with either acid or alkaline etch chemistry.

Sun Chemical offers a full range of etch and plating resists for printed circuit boards that can be used with either acid or alkaline etch chemistry.