SEPAREL hollow-fiber degassing modules can help prevent pinholes, cracking and “sputtering” often associated with the production of thin films and coatings. Unwanted outgassing can cause issues in your production.

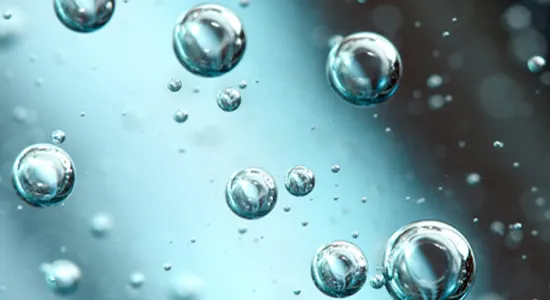

SEPAREL membrane degassing modules remove dissolved gases, such as oxygen and carbon dioxide, from liquids. Passing fluid through a membrane of bundled hollow fibers dissolves impurities such as nitrogen, carbon dioxide, oxygen, and other material, thereby increasing the purity.

SEPAREL membrane degassing modules help to:

- Prevent Coating Defects – Remove unwanted gas from your process

- Provide Smooth Appearance – Degassing can help prevent pinholes, cracks and “sputtering”

- Less Waste – Proper degassing can help reduce noncompliance