SunDigiProof

Color-Accurate Inkjet Swatches Printed Onsite and On Demand – SunDigiProof:

Color-Accurate Inkjet Swatches Printed Onsite and On Demand – SunDigiProof:

Converters often face repeated requests to create multiple color swatches to send to your brand owner customers for approval. We know that this manual process can be very time-consuming for you and, if there is no ink kitchen on site, can necessitate the requests being sent back to your ink suppliers to fulfill, which can cause delays in the color approval workflow.

To accelerate the process, save time and cut out the manual handling, Sun Chemical has developed SunDigiProof, a service that enables the production of color-accurate inkjet swatches, printed onsite and on demand for the flexible packaging market.

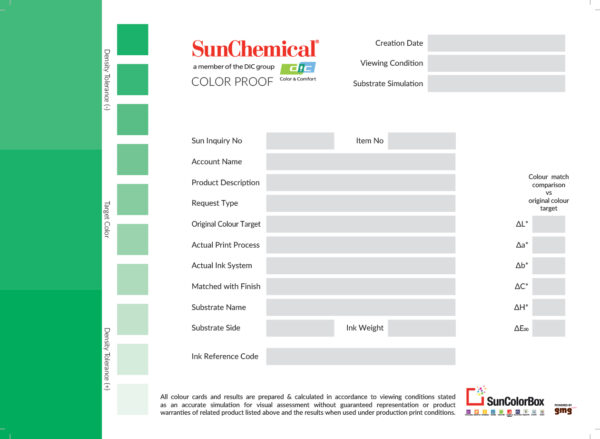

The SunDigiProof solution is available as Seine or GMG ColorCard to fit customers’ technical and price point requirements, giving supply chain partners faster and more productive ways to reduce cost, drive innovation and provide flexibility.

Using the latest Epson inkjet proofer and papers to simulate the gloss level of the final product (rather than printing on the actual production substrate), you can reproduce the manual process and create a digitally printed version of the physical standard that is exactly repeatable and has improved reliability over wet proofing.

For printing on paper and boards, users can specify the desired level of texture to apply to simulate the appearance of the substrate.

Both Seine and GMG ColorCard have a feature to print Munsell type charts, which are a very effective way to visualize how a color varies in all directions of the color space around the standard. You can set the level of variance around the points of the color space and decrease or increase the level based on the specific tolerance you wish to show to a brand owner.

For the metal decorating market, Sun Chemical offers an additional digital proofing solution.

Learn more about our collaboration with GMG ColorCard in this GMG news release or this webinar.

Customer Testimonial

VPK Packaging have implemented SunDigiProof Seine at their production site in the Netherlands.

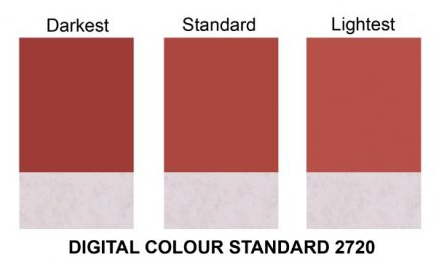

“When we have to introduce a new color into our workflow, we create a color accurate digital proof with SunDigiProof Seine. This is then communicated to the customer for approval, including the light and dark limits (shown below) and then the same digital standard data is used in production for press side quality control. For one of our major customers, we used this process to produce new orders and had no issue meeting their expectation and delivering on all designs for color.”

- -VPK Packaging

Resources

Feel like learning more? Download our SunColorBox Guide.

Request