The SEPAREL Difference

- The simple structure results in few breakdowns.

- Unique pipe distribution system controls the specific resistance value and has excellent stability.

- Long lifespan of the carbon dioxide gas injection module.

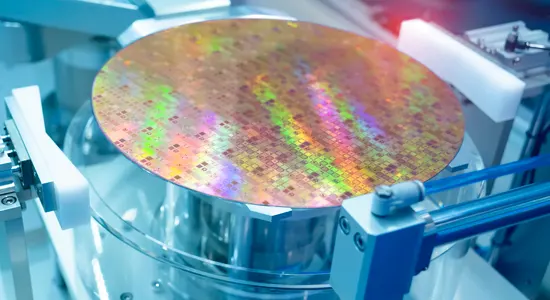

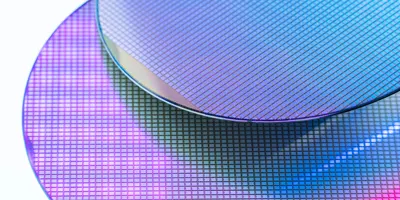

![]() SEPAREL membrane degassing technology can help reduce the stationary charge that builds up on the surface of a material. For example, electrostatic overstress (EOS) and electrostatic discharge (ESD) can lead to field failures in semiconductors.

SEPAREL membrane degassing technology can help reduce the stationary charge that builds up on the surface of a material. For example, electrostatic overstress (EOS) and electrostatic discharge (ESD) can lead to field failures in semiconductors.

The SEPAREL membrane degassing module and eFLOW Series may help to control the specific resistance value of ultra-pure water by supplying carbon dioxide through a hollow fiber gas permeable membrane uniquely developed by DIC.

This makes it possible to avoid dust re-adhering, and to prevent static electricity damage to the substrate pattern.