Membrane Water Degasification Technology

Membrane water degasification technology can be used for several water treatment processes to purify water.

DIC Corporation’s SEPAREL® membrane degassing modules remove dissolved gases, such as oxygen and carbon dioxide, from liquids. Passing fluid through a membrane of bundled hollow fibers dissolves impurities such as nitrogen, carbon dioxide, oxygen and other material, thereby increasing the purity.

Principal applications include ultrapure water production, electronic components, ink systems, film and coating, medical and analytical devices and anti-static to name a few. Applications for these modules also include solvents.

See below for a sampling of our broad range of degasification solutions for each of these applications.

Membrane water degasification technology can be used for several water treatment processes to purify water.

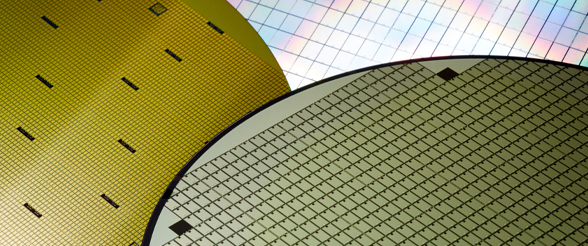

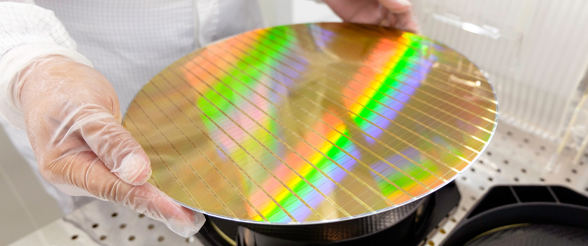

SEPAREL® membrane degassing technology can be used in a wide range of applications in the front-end processes of semiconductor chip processing.

SEPAREL® hollow fiber membrane technology delivers unmatched degasification of digital inkjet ink.

SEPAREL® hollow-fiber membranes can reduce water vapor passing through surface skin membranes to improve the accuracy of medical analysis results.

SEPAREL® hollow-fiber degassing modules can help prevent pinholes, cracking and “sputtering” often associated with the production of thin films and coatings.

The SEPAREL® membrane degassing module and eFLOW® Series can help reduce stationary charge that builds on a material surface.